SPM Engineers is Dss Pipe Clamp With Purging Arrangement Hydraulic. We are offering different sizes of clamps for your valuable pipeline projects starting with 14” diameter.

The Purge Preventing Systems in the range manufactured by SPM Engineers are designed around the principle of using 2 silicon purging tubes to create a seal on either side of the weld, just far enough away from the weld not to be affected by heat but close enough to the joint to provide the fastest weld purge time. Once ready to start purging, the system is inserted into the bore of the pipe using a reach rod to center the system to the weld gap.

When the gas flow is started, the silicon purging tube inflates and upon reaching the pre-set pressure, the valve releases the gas gently into the weld chamber to purge the interspace without turbulence. The Oxygen is removed from the weld chamber through the integral exhaust outline provided in the system. Used in conjunction with Oxygen Monitors to indicate when the required low level of oxygen has been reached, welding can then commence, with the inert gas enabling the welder to produce an even oxidation-free penetration weld bead. Afterward, the silicon purging tubes are deflated simply by operating the valve in the panel box and taken back the preventing system easily.

Feature & Advantages:-

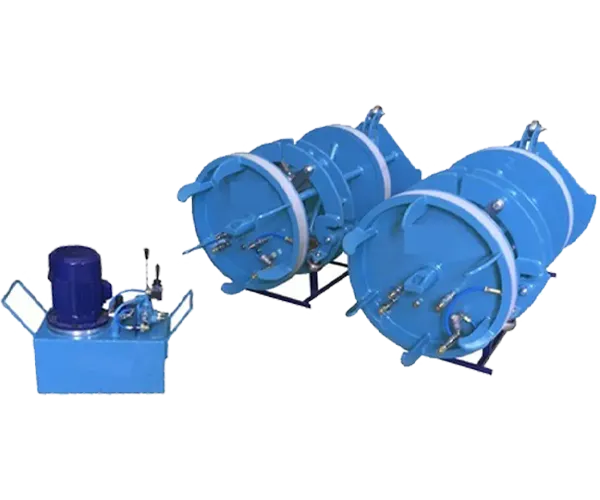

![]() Dss Pipe Clamp With Purging Arrangement Hydraulic covers a range of diameters and is adjustable for wall thicknesses within the specific range.

Dss Pipe Clamp With Purging Arrangement Hydraulic covers a range of diameters and is adjustable for wall thicknesses within the specific range.

![]() Dss Pipe Clamp With Purging Arrangement Hydraulic is adjusted to the required setting by SPM according to the pipe wall thickness.

Dss Pipe Clamp With Purging Arrangement Hydraulic is adjusted to the required setting by SPM according to the pipe wall thickness.

![]() Dss Pipe Clamp With Purging Arrangement Hydraulic requires flattens air pressure from a compressor.

Dss Pipe Clamp With Purging Arrangement Hydraulic requires flattens air pressure from a compressor.

![]() Alloy Steel wheels provided clamps for smooth traveling.

Alloy Steel wheels provided clamps for smooth traveling.

![]() SPM Pneumatic Pipe Welding Clamp is an exemplary choice for the construction of oil and gas pipelines.

SPM Pneumatic Pipe Welding Clamp is an exemplary choice for the construction of oil and gas pipelines.

![]() Separately operated Pneumatic jaws allow the line of pipes with different wall thicknesses.

Separately operated Pneumatic jaws allow the line of pipes with different wall thicknesses.

![]() The adequate lineup at the next joints is assured by a reserve air tank.

The adequate lineup at the next joints is assured by a reserve air tank.

![]() Conversion kits for various pipe sizes are available upon request.

Conversion kits for various pipe sizes are available upon request.

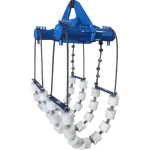

![]() The Internal Line up Clamp Pneumatic works inside the pipe. Roller-type actuating jaws hold the pipe ends to assure an adequate alignment of two pipe joints for external welding.

The Internal Line up Clamp Pneumatic works inside the pipe. Roller-type actuating jaws hold the pipe ends to assure an adequate alignment of two pipe joints for external welding.

![]() Available in size 16” & above size available on request.

Available in size 16” & above size available on request.